Description

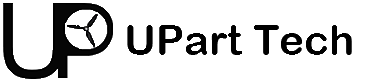

Ture X design, pure 3K carbon fiber.

Comes with GoPro mount, ample equipment installation space;

Omnidirectional arm locking structure to ensure the connection strength between the arm and the body;

The unique motor base design ensures installation speed and high strength;

Product Name:iXC15 X Class Frame

Wheelbase: 950mm

Carbon tube arm dimension:20mm*20mm*425mm

Tube:20mm(out OD),18mm(inner OD)

Singles Tube Length:375mm

Arm Thickness: 6mm

Bottom Plate Thickness: 3mm

Top Plate Thickness: 2mm

Upper Plate Thickness: 3mm

Camera Plate Thickness: 3mm

Motor Mounting:19x19mm - 25*25mm

VTX Mounting:30.5*30.5mm / 20*20mm

Weight: 643rams (Included no TPU Parts)

Detailed Information

There’re more and more pilots becoming interested in racing bigger drones because mini-quads are reaching their performance limits, but X Class drones have lots of room to grow. Most of the large size gear that we used was created for aerial video platforms. They have the lifting power, but they’re not built for speed or the responsiveness that we need when we’re racing. That’s why iFlight release iXC15 950mm X CLASS racing frame.

iXC15 is the first X CLASS drone of iFlight.It’s finally released after half a year of developing and testing. This is one of the most amazing frames while the most flexible frame designed and developed by the iFlight R&D team. This time, iFlight still stands at the forefront of the market. Let's take a look at the development of iXC15. Mounting Screw Pattern fits most motors on the market, which greatly facilitates the motor installation and eliminates the need to add the motor adapter seat. It helps reducing arm front end weight, thereby improving the flexibility of the frame. The motor base is locked to the arm via two crisscrossing standoffs, wherein the outer center is strengthened which makes the frame stable, reliable and easy to adjust.

The arm and the mounting part of the frame body are fixed by two crisscrossing “Power- Lock” M5 long screws & M5 nut. Besides, two vertical side plates have added to each arm to make the arms and the body more secure. This fixing method is not only reliable but also makes replacing and repairing arms easier on site. In addition, a flexible 3D print antenna mount is used at the rear of the body to secure the tail antenna for easy antenna installation.

Refer to the frame body, two simple but rigid 3mm thick top & bottom plates are used, providing large space to install equipment. iXC15 has been improved in every part during development, from the first sample to the final mass production. It took half a year- 6 times of proofing-from round tube to square tube, continuous improvement, and testing, and finally released.

iXC15, the perfect design, coupled with incredible performance, gives you a more enjoyable flight experience.

Price & Procurement

Associated Product

-

-

-

-

-

-

Capacity: 300 mAh Nominal voltage: 3.8 V Maximum discharge current: 60C ...

-

DarkStar20: So light, it makes feathers look overweight. Perfect for sneaking th ...

-

With 20A Blheli_s ESCs and an integrated ELRS RX, this FC lifts your drone’s per ...

-