Description

5mm titanium alloy shaft, our strongest prop shaft ever!

Smooth and long-lasting NSK 10x4x4 bearings

Center slotted N52H curved arc magnets

XING O-ring bearing gap protection

Crash resistant 7075 aluminum bell

Motor wires protector

Dynamically balanced

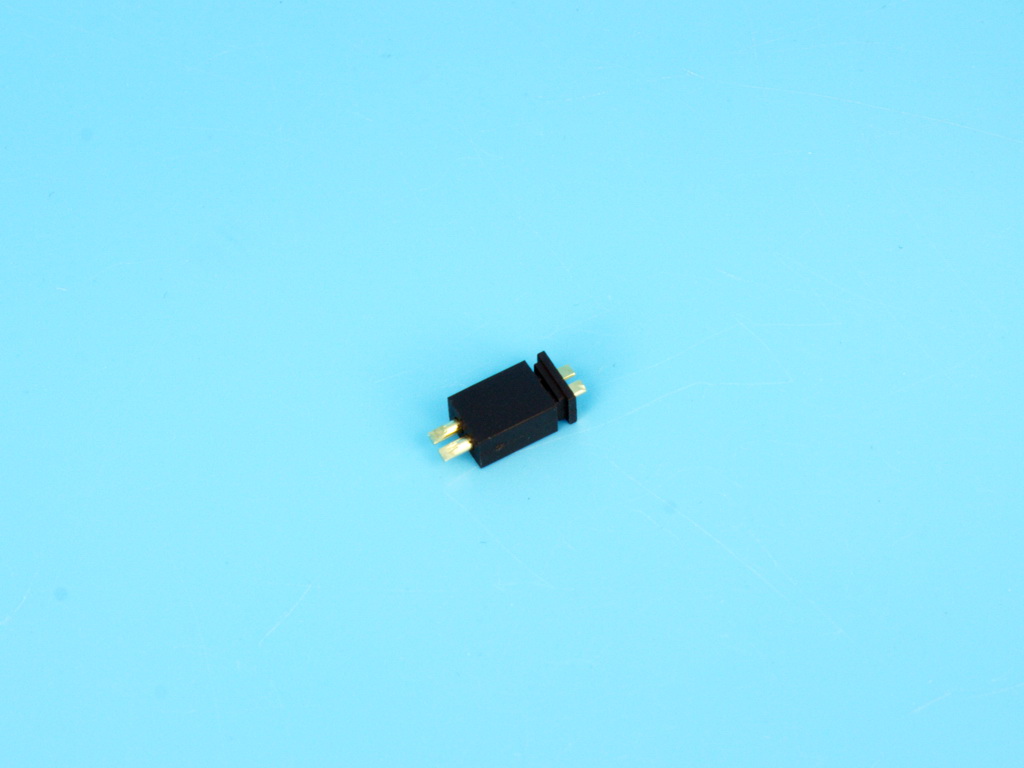

Model: XING2 2506 Black Motor

KV: 1500KV / 1850KV

Weight(included wire): 38.2g / 40.2g

Dimension: φ31.7*19.6mm

Interphase Resistance: 74.88mΩ / 64.33mΩ

Input Volts: 25.2V

Peak Current: 33.26A / 41.55A

Max Watt: 817.5W / 1013W

Mounting Holes: 16*16 φ3mm

Rotor Specifications: Unibell

Shaft Diameter: 5mm

Shaft Protruding Length: 15mm

Lead: 160mm-20AWG / 200mm-18AWG

Magnet: N52H Curved

Configuration: 12N14P

Bearing Type: NSK

Bearing Specification: φ10*φ4*4

Winding: Single Strand copper winding

Detailed Information

Our XING series NextGen motors have become popular after the initial release in 2018 and became the new standard on the market. Was it the curved shape or the internal damping ring to protect the bearing, or was it the higher quality NSK bearings coupled with a higher grade titanium alloy shaft? We've been copied and compared all these years, but now it's time to set a new standard again! We're finally ready to announce our predecessor the XING2!

The smooth, reliable and powerful XING motors were upgraded and we achieved an even higher standard in our manufactory as well as better performance than ever before. New center slotted N52H curved arc magnets were introduced to drastically reduce response time of the motor! Maybe the biggest bottleneck of our FPV flight controller is the motor due to it's translation delay of it braking and accelerating. XING2 motors offer faster response to translate your PID loop quicker and get that locked-in feeling you were always looking for!

Due to the high quality materials used and the durable joint of bell and shaft, we were able to reduce the magnet air gap and stator lamination to a minimum. The smaller the air gap is, the lower that reluctance and the higher the magnetic flux (which is the magnetic analog of current) causing more efficiency and higher power!

Price & Procurement

Associated Product

-

-

-

-

-

-

Capacity: 300 mAh Nominal voltage: 3.8 V Maximum discharge current: 60C ...

-

DarkStar20: So light, it makes feathers look overweight. Perfect for sneaking th ...

-

With 20A Blheli_s ESCs and an integrated ELRS RX, this FC lifts your drone’s per ...

-